Introducing the Levitation Conference Table: a monumental piece that blends elegance with modern technology.

In the world of luxury design, where innovation meets craftsmanship, a new masterpiece has emerged from the collaboration between Antoine Jourdan, designer, and Maison Tournaire, an eminent French jeweler.

The concept of the Haute Couture furniture range is based on sculptures made by Maison Tournaire, which are combined with steel and wood to create furniture that is both modern and artistic. A surprising mix of bronze, powder-coated metal, and solid wood.

This article delves into the fascinating details of its design, from the sophisticated material choices to the functional integration of technologies, revealing how this table is not just a piece of furniture, but a true work of art designed to enhance the most exclusive meeting spaces.

The various stages from design to manufacturing.

1. 3D design

2.2 The design of the solid American walnut tabletop: Gluing and cutting of the tabletop.

The design of the Levitation Conference Table’s top begins with the careful selection of solid American walnut, known for its strength and beautiful natural grain. The manufacturing process starts with the gluing together of multiple boards of carefully chosen walnut to form a cohesive block. This step is critical to ensure not only the uniform aesthetics of the tabletop but also its long-term durability.

2.2 The design test of the bevel before cutting the tabletop.

Once the gluing is completed, the tabletop is meticulously cut to the precise dimensions of 4.3 meters in length. This cutting is performed using high-precision tools to ensure sharp edges and a flawless finish.

2.3 Cutting out the spaces for the casings

3. The varnishing of the tabletop

4.1 The design of the sculpture by Mathieu Tournaire

The integrated sculpture in the Levitation Conference Table is the work of Mathieu Tournaire, the general and artistic director of Maison Tournaire, known for its unique approach in the field of jewelry. For this particular creation, Mathieu drew on his expertise in transforming precious metals to design a sculpture that embodies both innovation and tradition. Using bronze and gold, iconic materials of the Tournaire Décor brand, he envisioned a piece that not only aesthetically supports the walnut top but also adds a deep artistic dimension to the entire table with elements oriented towards justice.

This monumental work was commissioned by a renowned firm of notaries and lawyers.

The design of this sculpture involved advanced casting techniques and meticulous finishing to ensure that every detail reflects the excellence and elegance characteristic of Maison Tournaire’s creations.

4.2 The casting of the sculpture and wax figures

The technique of lost-wax casting is an ancient and sophisticated process used to create metal objects with great precision and fine details. Here is how it works:

Wax Model: It all starts with the creation of an original model of the object to be made, crafted in wax. This model is often hand-carved or molded to capture all the fine details of the desired design.

Ceramic Mold: Once the wax model is ready, it is coated in multiple layers of refractory materials, such as ceramic, forming a sturdy mold. Each layer must dry and harden before the next is applied, creating a solid shell around the wax.

Wax Elimination: The mold is then heated in a kiln. The heat melts the wax, which flows out of the mold, leaving a hollow cavity that replicates the shape of the original model. This is why it is called “lost wax.”

Metal Pouring: Molten metal is poured into the empty mold. Since the wax has been completely removed, the metal occupies the space left by the wax, thus replicating all the details of the original model.

Cooling and Demolding: Once the metal solidifies, the ceramic mold is broken to reveal the metal object. This process is irreversible, as the mold is destroyed, making each cast piece unique.

Finishing: The metal object can then undergo finishing works, such as polishing, deburring, and sometimes patinas or other surface treatments to enhance its appearance and preservation.

4.3 The casting of the sculpture in Bronze: sanding and patination of the sculpture.

Mathieu Tournaire applies the artistic finishes to the sculpture.

5.1 Mathieu Tournaire applies the artistic finishes to the sculpture.

Made of steel, the legs are first cut and then precisely shaped to achieve their unique form. After shaping, the legs undergo a powder coating process, a technique that involves the application of a powder that is then baked in an oven, giving the legs a durable matte black finish that is resistant to scratches and corrosion.

This finish not only protects the metal; it also adds a touch of sophistication and modernity to the overall design of the table.

5.2 Arrival at the Réol workshops of the matte black fine texture powder-coated legs.

Dominique Réol and his team bring all the expertise and know-how for the finalization of this unique piece.

6. Arrival at the workshops of the 4.30 meter long solid walnut tabletop.

7. The positioning of the legs for routing to allow them to be embedded in the solid wood.

The positioning of the legs for routing is a crucial step to ensure that they are perfectly embedded in the solid wood of the tabletop. This procedure starts with the precise marking of the locations on the wood where the legs will be attached. The teams at Réol workshop perform meticulous craftsmanship.

8. Routing of the legs and assembly testing at the Réol workshop.

This process must be executed with great precision to ensure that the legs fit exactly and securely into the tabletop, which is essential for the table’s stability and durability. Once the routing is complete, the legs are inserted into the prepared slots and securely fastened, allowing for a seamless integration with the solid wood.

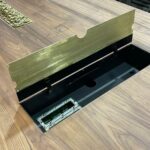

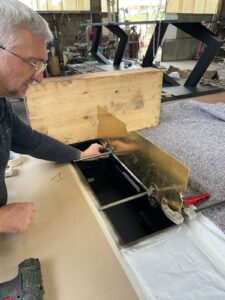

9. The installation of the casings

The installation of the casings by Dominique Réol and his teams in the Levitation Conference Table is a crucial step to integrate technological features while preserving the aesthetics of the furniture.

These casings, made from solid steel and brass, are designed to house the electronic equipment needed during meetings, such as cables, electrical outlets, and connectivity systems.

10. Routing of the wood for the inlay of the Tournaire sculpture and final test of the table assembly.

Routing the wood for the inlay of the Tournaire sculpture is a step that requires precision and artisanal craftsmanship. A cavity is carefully carved into the solid walnut tabletop, precisely to the dimensions of the bronze and gold sculpture. This process must be carried out with great precision to ensure the sculpture fits perfectly into the tabletop, with no visible gaps, thus creating a seamless continuity between the wood and metal.

Once the routing is complete, a final test of the setup is conducted to ensure that the sculpture is correctly inserted into the wood.

This testing phase is crucial to verify not only the fit of the sculpture but also the structural integrity and aesthetics of the table. The goal is to ensure everything is perfectly aligned and secured before proceeding with the final finishes, thus guaranteeing that the table is ready for use and presents the desired visual appearance.

11. Le collage des feutrines sous les piétements

12. The gluing of felt pads under the legs

13. The shipment, unloading, and final installation of the piece.

The shipping, unloading, and final installation of the table require meticulous planning and execution to ensure that the piece arrives in perfect condition at its destination. Due to its monumental size and delicate components, the table is first carefully packaged and secured for transport.

Upon arrival, a specialized team handles the unloading with the help of equipment suited to safely manage the weight and size of the table.

The final installation is carried out on-site by experienced professionals. They assemble the various components, including the precise insertion of the Tournaire sculpture and the adjustment of the legs. This phase also includes the final mounting of the casings and the verification of all electronic connections.